Liquid Level Gauge is designed to view liquid levels using clear or red line Borosilicate tube to observe liquid levels. All valves use a stuffing box configuration to seal the glass tube, and have a ball check shutoff to prevent loss of vessel contents in case of glass failure. Operating pressure and temperatures are subject to the limitations of the tubular gauge glass and washer composition.

Glass tube level gauge is a kind of direct reading liquid level measuring instrument, which is suitable for the spot detection of liquid position in the general liquid storage equipment in the industrial production process. It is simple in structure and accurate in measurement. It is a traditional spot liquid level measuring tool. Generally used for direct detection.

Body material:304SS,316SS,Carbon steel,Bronze,etc

Sealing:Rubber,etc

Glass tube:Borosilicate glass,clear or redline.

Protective tube:Stainless steel or bronze

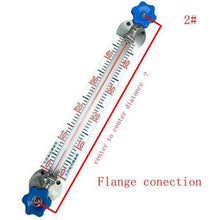

Connection:Thread connection or Flange connection,1/2’’ or 3/4’’ male NPT.

These valve bodies are rated for 500 PSIG at 450F. The actual pressure limitations are of the wall thickness of the glass tube,at the same time the work temperature is the other factors of influence of pressure. These sets are usable with oils and petrochemical liquids. Use with water or steam is not recommended due to the possibility of the steel valves developing rust or corrosion.

The following pressure values are for industry standard high pressure gage glass use. The steam services values are for reference only. For actual steam service, choose stainless steel valves.

Necessary information supplied before place order:

1,Center to center distance.

2,Thread diameter.

3,Body material.

4,Glass tube diameter

Additional information

1,Medium in the tank.

2,Work temperature and work pressure