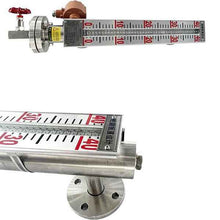

Magnetic flap level gauge (also known as magnetic float level gauge) is developed according to the principle of buoyancy and magnetic coupling. When the liquid level in the measured container rises and falls, the magnetic float in the liquid level gauge tube also rises and falls, and the permanent magnetic steel in the float is transferred to the magnetic flip column indicator through magnetic coupling, driving the red and white flip columns to flip 180°. When the liquid level rises, the flip column changes from white to red, and when the liquid level falls, the flip column changes from red to white. The red and white junction of the indicator is the actual height of the liquid level inside the container, so as to achieve a clear indication of the liquid level.

Characteristics

1, A wide range of applications, various installation forms, suitable for any medium level, interface measurement.

2,The tested medium is completely isolated from the indicated structure, with good sealing performance, leakage prevention, suitable for liquid level measurement under high pressure, high temperature and corrosion conditions, with high reliability.

3, Set field indication, remote transmission and change, alarm control on one and can be adjusted freely, fully functional two-color indicator with luminous, continuous and intuitive, eye-catching, large measuring range, observation direction can be changed arbitrarily.

4, Good vibration resistance, can adapt to the situation of liquid level fluctuation, simple structure, convenient installation, low maintenance cost.

Cautions:

- For the level gauge over a certain length (ordinary type >3 meters, anticorrosive type >2 meters), it is necessary to increase the middle reinforcement flange or ear climbing as a fixed support, to increase the strength and overcome their weight.

- The installation position of the magnetic flip plate liquid level gauge should be avoided or far away from the import and export of the material medium to avoid rapid changes in the local area of the material fluid, affecting the accuracy of the liquid level measurement.

- When equipped with a remote transmission instrument, the following shall be done.

- The remote transmission instrument should be close to the leading pipe of the liquid level gauge and fixed with a stainless steel hoop (iron is forbidden).

- The induction surface on the remote transmission instrument should face and be close to the leading pipe;

- When debugging should be opened the upper guide tube valve, then slowly open the bottom valve, let the medium smoothly into the main pipe (should be avoided in the operation of the media rushed float, float play column fluctuations caused, affect the display accuracy), observe whether magnetic turn red and white ball is normal, then close the tube valve, open the drain valve, let the led tube liquid level drops, this method for three times, It is normal and can be put into operation (except corrosive and other special liquids).

7 should be according to the medium situation, do not regularly clean the leading tube of the magnetic plate level gauge to remove impurities.